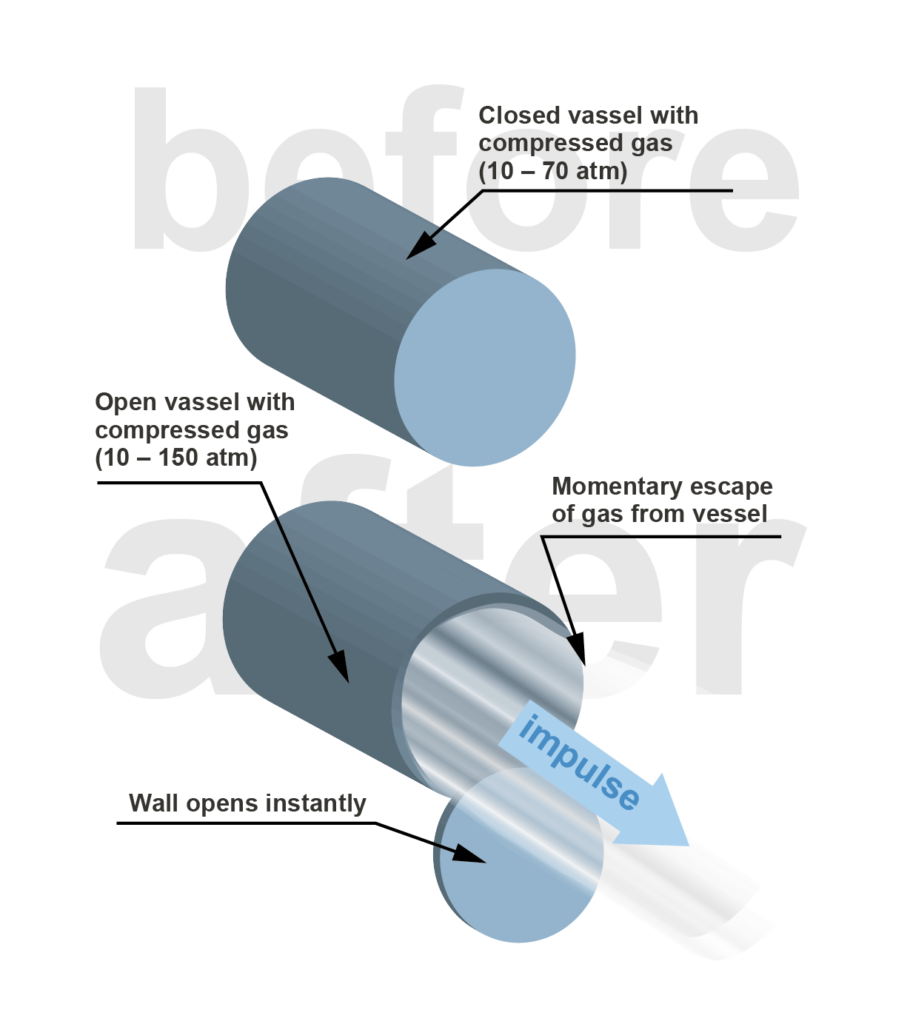

It is known that for the generation of a sharp (explosive) gas pulse, it is necessary to create a break in the thermodynamic parameters. Such a gap is created, for example, in a chemical explosion, when the temperature and pressure of the gas increase instantly in a confined space. On the other hand, in a closed vessel with a compressed gas there is also a rupture surface with respect to the external atmosphere, and this surface coincides with the shell of the vessel. Imagine that this wall instantly disappears completely. Such examples are widely represented in the Internet. For example, when a soap bubble bursts, the velocity chamber fixes the formation of a pulse even with a very small differential pressure.

Now imagine a vessel with a compressed gas to high pressure (for example, dozens of atmospheres), where the wall suddenly disappears completely. The gas will flow into the surrounding space at supersonic speed. In this case, the internal energy of the gas will be converted into kinetic (impulse) with the maximum possible efficiency. If we take into account that the potential energy is determined by the pressure of the compressed gas and the volume of the vessel, then at a finite efficiency the energy conversions can generate significant impulses, and without the use of any pyrotechnic means. Obviously, based on this phenomenon, it can be created many useful products.

Our solutions

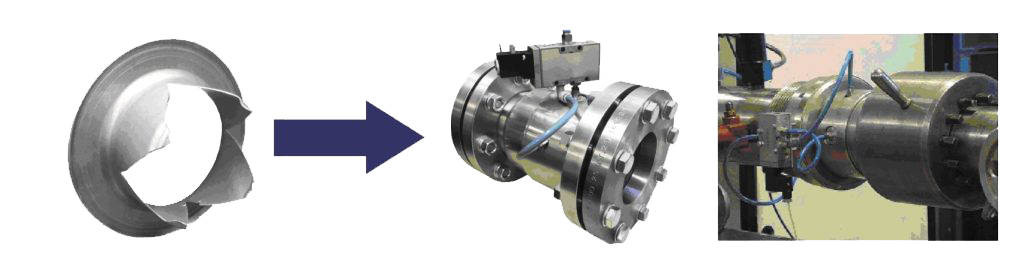

Until now, there was no commercially available means for instantly destroying the shell of such a vessel. One can only recall that for decades a practical tool of this energy transformation of compressed gas was destructible diaphragm in the impact tubes, the main drawbacks of which are impossibility of its repeated use and instability. Its have served the research of high-speed gas flows in university laboratories well, but its have not allowed the creation of widely used market products because after each cycle it is necessary to replace the destroyed diaphragm.

The ISTA Scientific and Production Enterprise first developed a family of controlled air high-speed valves of the KB-20, KB-40 and KB-80, which have the basic characteristics (areas and opening times) that are not inferior to diaphragms being destroyed in the impact tubes, but providing multiple controlled operations. It is important to note that on the impact tube, equipped with such a valve, the labor productivity of researchers grows many times.

Over the past 25 years, the Scientific and The ISTA Scientific and Production Enterprise has managed to create a number of market products based on the aforementioned valves under the Speed Valve technology general name, which in many products allowed generating the same impulse as in a chemical explosion. The name comes from the English abbreviation SV Technology (Speed Valve technology).

The above properties of the KB series valves have allowed to create the following product lines:

- No-diaphragm impact tubes for the study of high-speed flows. Provide experiments conduction with high performance and repeatability.

- The air starting units, in particular portable rescue air line-throwing guns, which provide communication during rescue operations, which have already saved lives of people many times.

- High-speed air-core tire, operating at high pressures.

- Systems of air caving of bulk materials, hanging at the industrial facilities of their storage and transportation (bunkers, silos, overpasses, hoppers).

- Air impulse systems for intensification of heat and mass transfer processes in elements of industrial designs (heat exchangers, filters, cyclones).

- Effective sorting devices. Provide highly efficient separation and rejection of materials.

- Adaptive inflators of vehicle airbags (cool-smart-airbag). This technology is protected by patents of the Russian Federation, the USA and the Germany.

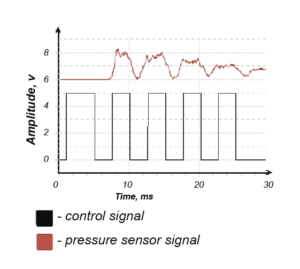

Valve “KB-28” operates at a frequency of up to 200Hz

In the left figure are shown timing characteristics of reaction of valve “KB-28” with a typical driving solenoid valve (lower curve shows the coil electric signal, upper curve shows the signal proportional to the valve outlet pressure). Pulse amplitude drop on the upper curve is caused by pressure drop in the receiver. This figure shows that such a valve can provide some complete cycles of opening/closing while filling the air bag that takes 30 – 100msec.

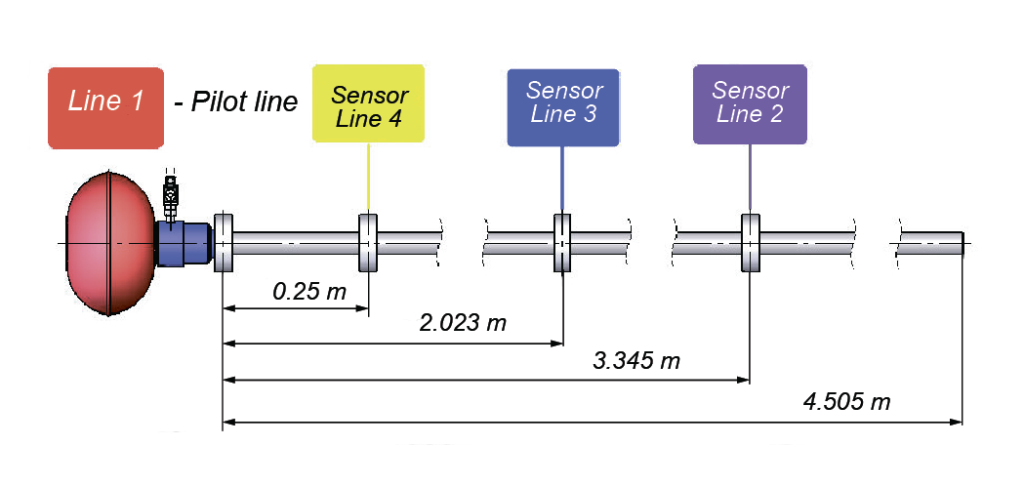

Aircannon “ISTA-3” is a powerful shock wave generator

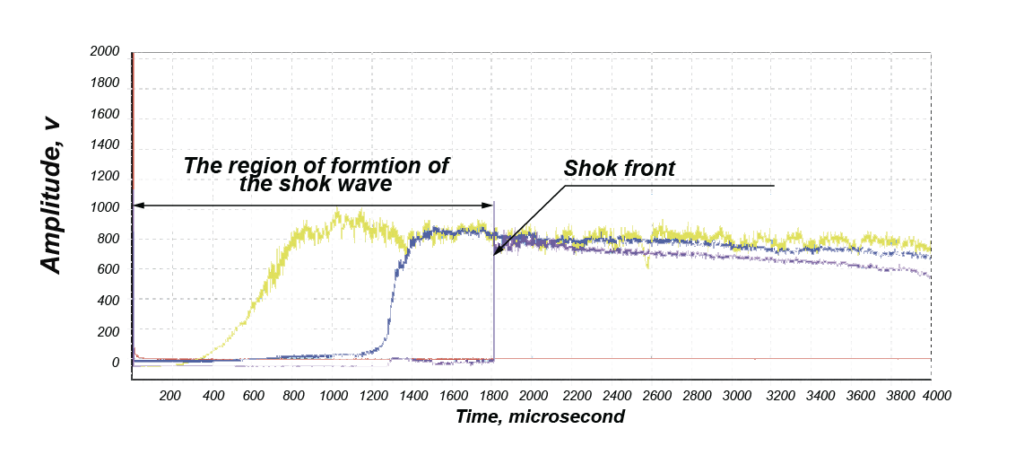

In the ridht figure is shown the installation diagram for studying the generation of shock waves in the pipe with typical aircannon “ISTA-3” with receiver of 5 litres capacity operating at the pressure of 0.6MPa. The pressure is measured with piezo sensors located at different distances of the aircannon. On aircannon actuating, the valve opens and compressed air is going from the receiver to the pipe.

The findings of the investigation into shock wave generation are shown in left figure. It is obvious that as it flows through the pipe, the compression wave front becomes sharper (yellow and blue curves), and at the length of the pipe of about 3 meters it turns into a shock wave (purple curve). It is well known the shock wave is characterized by an abrupt jump of thermodynamic parameters (including pressure) at the length of some angstroms.